List of service portfolio

Our Services

- Retrofit Service

- Dry Docking services

- Asset Management Services

- Naval Architectural Services

- Ship Sale and Purchase

- Green Ship Recycling

- Inventory of Hazardous Materials (IHM) Part I, II and III

- Preparing Bulk carrier for the carriage of containers

- Ship Chartering

- Energy Efficiency Existing Ship Index (EEXI)

- Pre-purchase Inspections

- Ship Spare parts

Retrofit Services

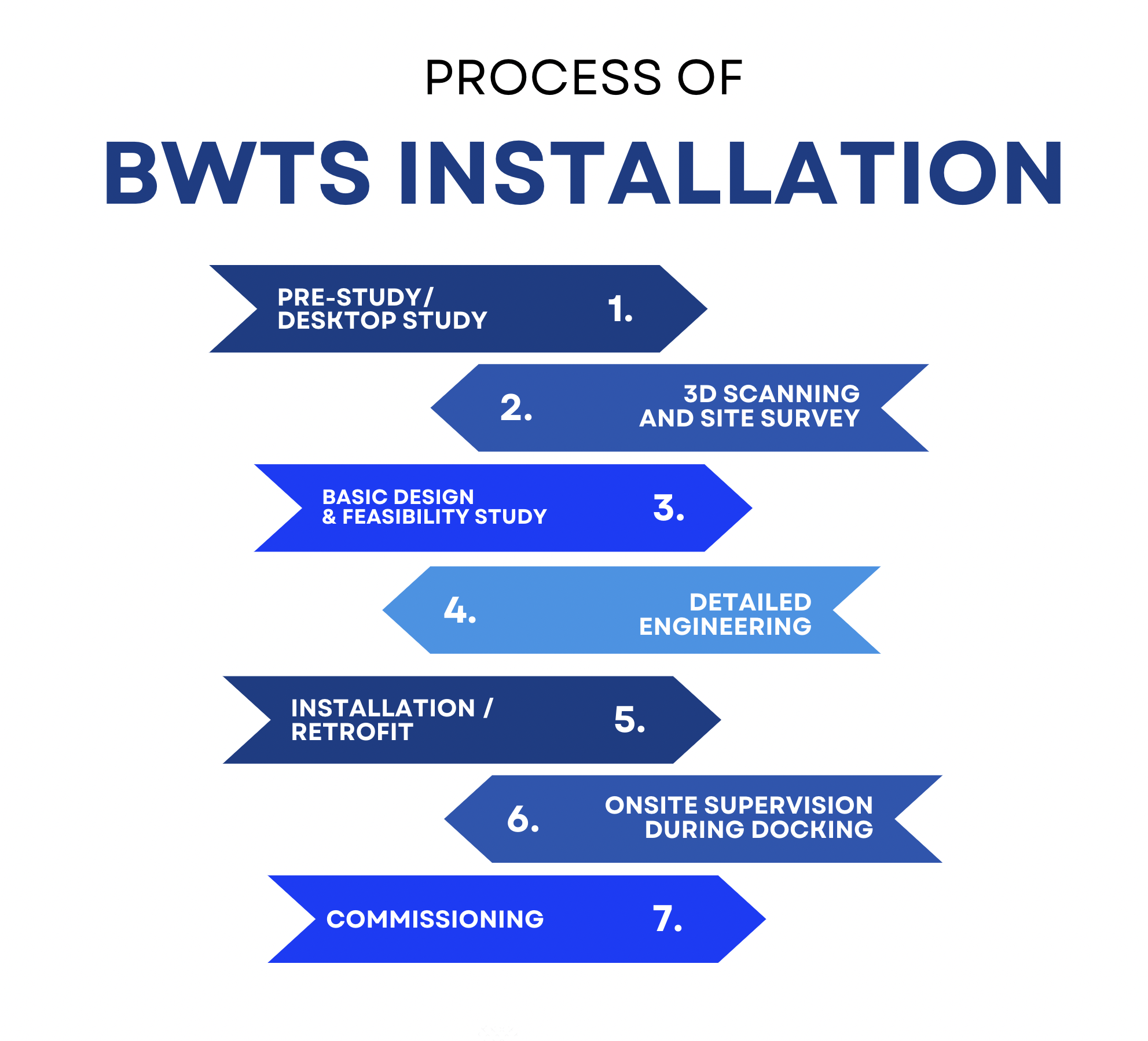

(a) Ballast Water Management System (BWMS) Retrofit services

In compliance with the regulations regarding Ballast water management system (BWMS) will be one of the biggest challenges for the shipping industry soon. Eventually, all relevant vessels shall need to have installed a Ballast water treatment system (BWTS) to inactivate invasive species and prevent the spread of non-native aquatic species in lakes, rivers, and coastal waters. The IMO implementation schedule for BWTS requires the ship to install a type of approved system.

We can help our clients from the pre study comparison of vessel pump capacity to the BWTS till Commissioning.

We are happy to assist our clients on turnkey basis.

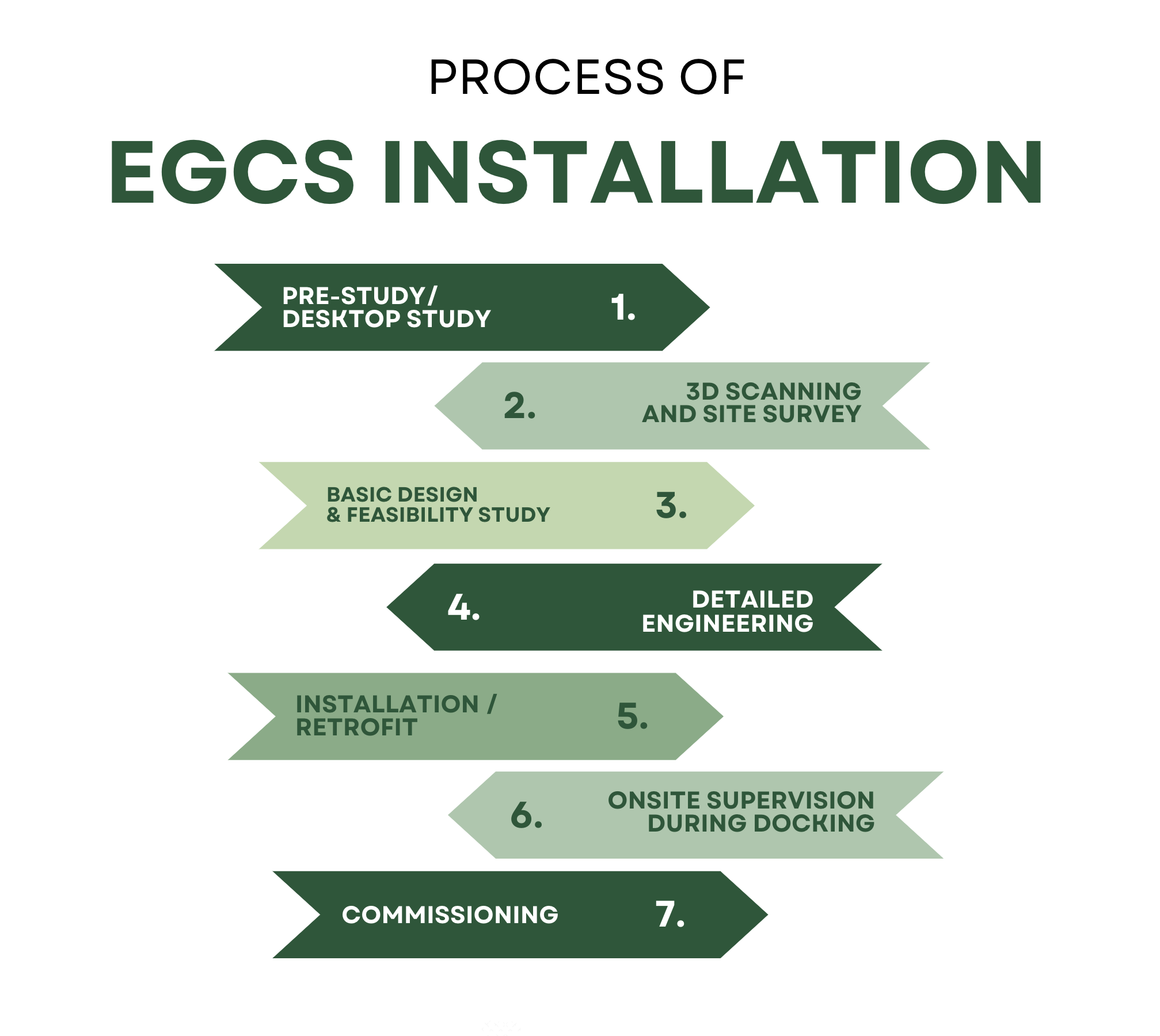

(b) Exhaust Gas Cleaning System (EGCS) Retrofit services

The International Maritime Organization (IMO) regulations mandate that the sulphur content in fuels, which is carried by merchant vessels, must be limited to 0.50% globally and 0.10 % m/m in ECAs (Emission Control Areas; The Baltic Sea Area, The North Sea area, The United States, Canada, and the United States Caribbean Sea area).

Before this, the maximum sulphur cap in fuels has been kept at 3.5% m/m. Compliance with the new regulations requires that vessels either use expensive fuel with low sulphur content or clean the exhaust gases by using exhaust scrubbing systems.

Exhaust gas scrubbers are being installed on a substantial number of ships to comply with international regulations and standards economically.

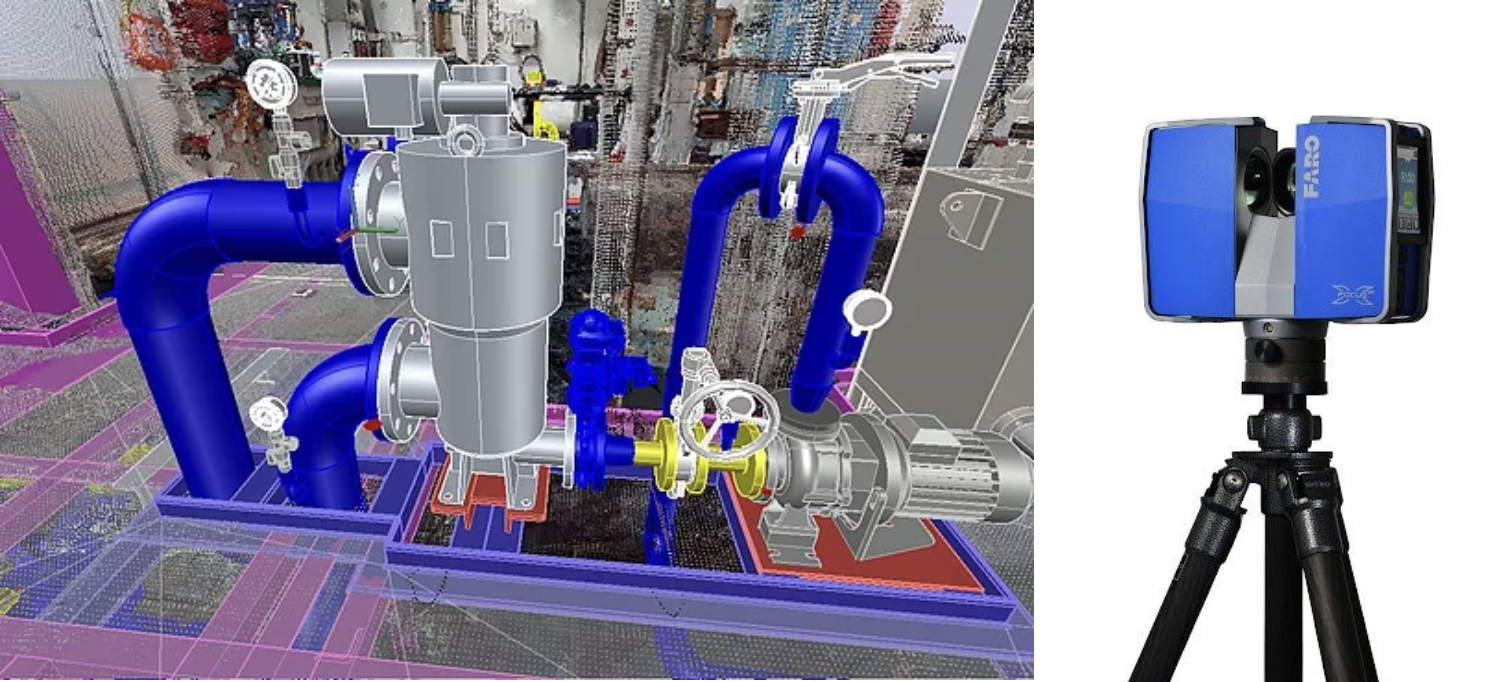

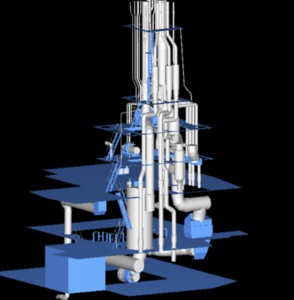

(c) 3D Scanning and point cloud modelling for ship modification / conversion

We can carry out 3D scanning onboard the ship and create 3D point cloud model for ship modification or conversion.

We can also carry out 3D scanning and model so that the asset can operate again.

(d) Air Lubrication System (ALS) Retrofit services

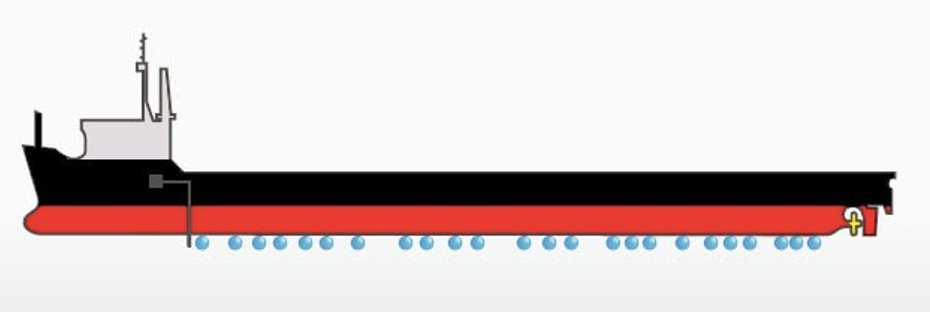

Air lubrication system (ALS) technology that reduces the frictional resistance of the vessel by creating a carpet of microbubbles that coats most of the flat bottom of a vessel’s hull. The microbubbles, measuring 1–3mm in diameter, are generated by air release units (ARUs) in the bottom of the hull.

PacMaK DB expertise will help our clients on the basic and detailed design of the Air lubrication system (ALS). We can do 3D scanning and site survey to find the feasible location for the equipment placement.

With the right ship hull design, the air lubrication system can generate substantial reductions of both fuel and CO2 emissions, with an associated decrease of the vessel’s operating costs.

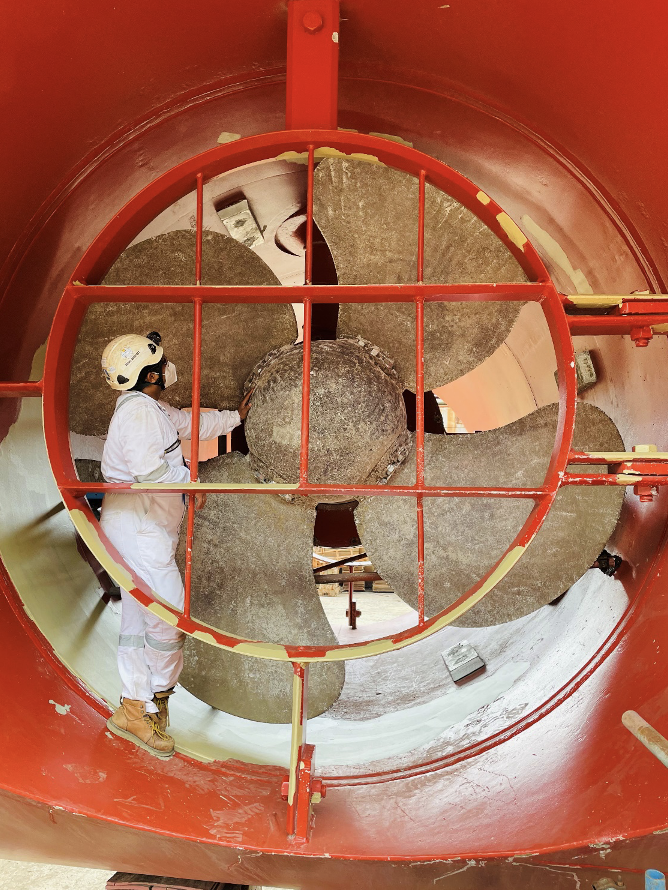

Dry Docking Services

(a) Docking superintendent supervision

We have experienced Naval Architects and Marine engineers with docking experience across various shipyards such as in China, Singapore, Malaysia, Indonesia, Bulgaria, Spain, Denmark, Durban, Netherlands, Germany, USA, etc.

We can take over the projects from the beginning of the docking till end of the docking by verifying invoices and work done carried out by shipyard.

(b) Docking steel repair supervision and inspections

Our experienced Naval Architects and Marine engineers with docking experience across various shipyards such as in China, Singapore, Malaysia, Indonesia, Bulgaria, Spain, Denmark, Durban, Netherlands, Germany, USA, etc.

We carry out welding inspection and steel repair supervision as per the scope of work.

(c) Steel quantum and painting area calculations

Our experienced Naval architects can calculate the steel quantum calculations according to the steel repair specifications.

Our expertise will help clients by calculating the painting area calculations according to the coating repair specifications as per IACS standards.

(d) Steel Repair Supervision for Damage/ Grounding Areas

Steel Repair supervision need to be carried out by experienced Naval Architect who will help to identify the defect of the repairs carried out.

Our experienced Naval Architect expertise team will help our clients in repair supervision and welding inspection on the repairs carried out at the yard.

Asset Management Services

(a) Condition Monitoring Programme (CMP)

Condition monitoring survey plays a key role in managing asset to avoid unnecessary repairs during docking

Our expertise in Condition monitoring survey will help our clients in assessing the condition of their asset to budget prior to docking and help them to maintain their asset on regular basis.

Our expertise will cover the following areas:

i. Ballast tanks – Coating and structural integrity

ii. Main deck plating and internals – Coating and structural integrity

iii. Main deck outfitting items – This will help our clients to prepare in advance for vetting inspection or flag state inspections or CAP survey in case of tankers.

iv. Void spaces – Will help to find out any structural defects due to hogging/sagging or any other stress in structures

v. Machinery spaces – Foundation of machineries will be missed item many times unless until where the major repairs have been found. Our expertise will help our clients to find out the condition of the foundation of machineries to avoid last minute surprises.

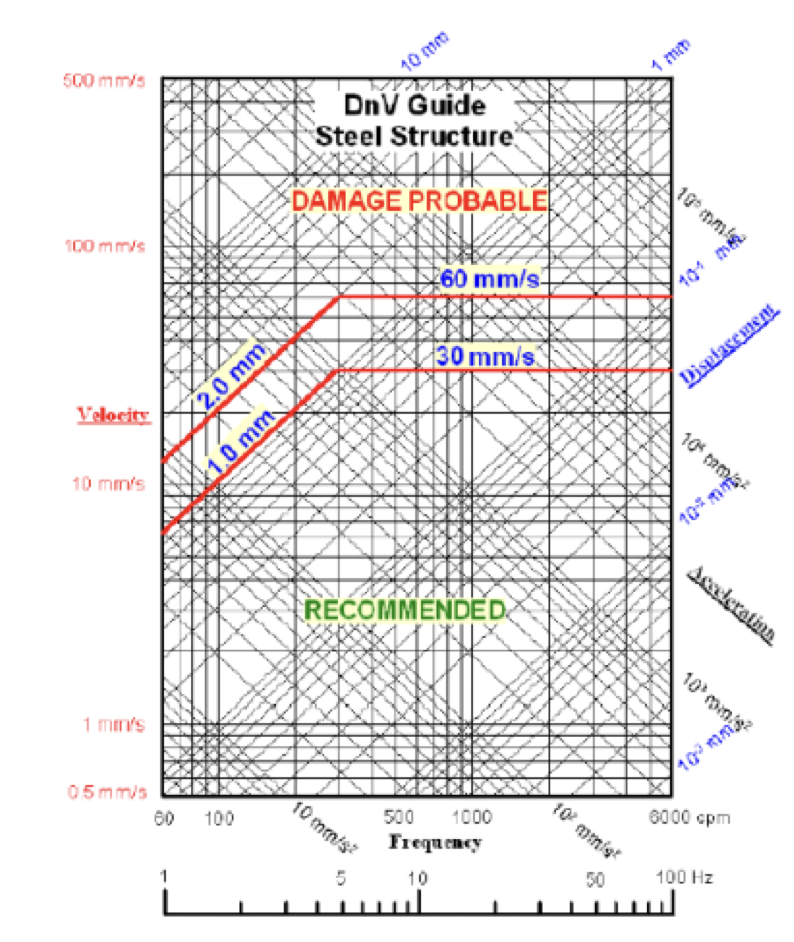

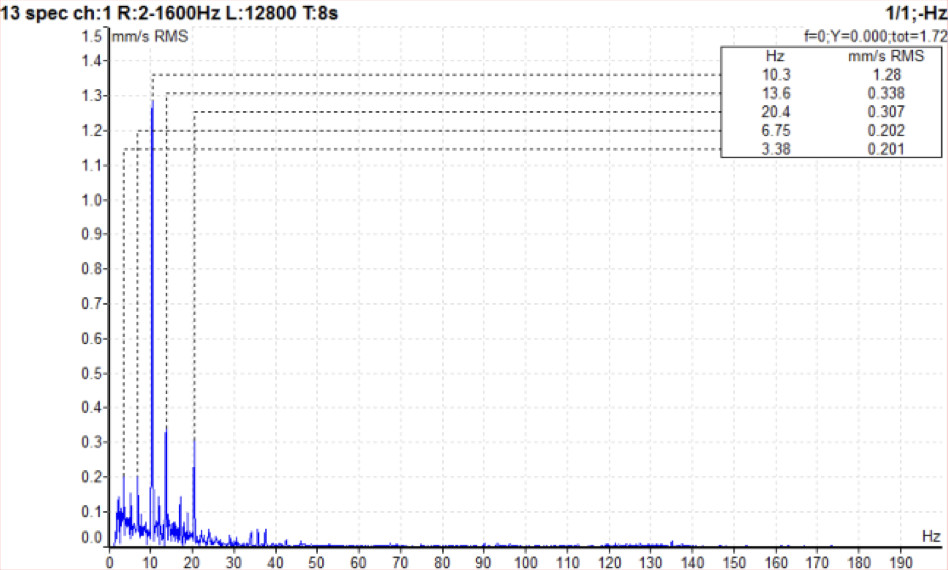

(b) Vibration Analysis

Ship vibration analysis involves the response characteristics (amplitude versus frequency) of the vessel structure or system in combination with various excitation(s), e.g., wave encounter, engines, propellers. This also includes discussion of vibration characteristics and conditions that may lead to resonance.

Hull Vibration Analysis

We carry out Hull Vibration as per our clients or flag state requirements.

Machinery Vibration Analysis

Our Vibrational analyst expertise will assist our clients in finding out

Vibration analysis will help our clients understand the condition of the machineries. This would lead to better maintenance of the machineries which would in turn prevent major repairs of pumps and motors.

(c) Noise Survey

In addition to our many other specialisation, noise survey is the primary and most significant. It has been determined that sustained exposure to the sound levels greater than 90dB can cause deafness and have impact on precision of on-board instruments and human health. The noise and vibration control has gained more relevance over time and there has been a rise in the awareness about prevention of permanent damage occurring because of sustained exposure to higher levels of noise and vibration.

(d) Coating Assessment Surveys

The coating system in ballast tanks is to be examined.

The condition of the coating in ballast tanks is assigned and categorised as GOOD, FAIR or POOR based on visual inspection and estimated percentage of areas with coating failure and rusty surfaces.

We have highly experienced and certified coating specialist teams for various marine and offshore assets.

We specialise being coating superintendent (assisting the overall Ship’s Project Superintendent) to obtain the best possible coating performance during drydocking by securing that the Shipyard and Paint supplier’s quality control meets with our clients’ needs and as per the standards.

We provide technical service to our clients (within the corrosion control market for Maritime and Offshore industry) to avoid technical coating failures.

We conduct pre-docking survey for the vessels tanks and general onboard structures to ensure no surprises when the vessel is in the dry dock.

(e) Damage Assessment Surveys

If your asset has undergone an accident, we will help you to evaluate the damage and give you guidance and support to bring your vessel back into operation as quickly as possible – without compromising on safety and reliability. Our team will survey the degree of damages of the hull by inspecting all the compartments likely to be affected by the collision.

Our experienced Naval Architects are qualified to attend the hull and damage claims.

Our competencies and services for vessel damage and repair management include:

- Support for the damage and repair of hull structures, propulsion and machinery systems, components, and rudder systems

- Assessment of residual hull capacity after grounding or collision

- Advice on weather restrictions for the voyage to a repair yard, if relevant

- Guidance and acceptance of repair procedures and drawings

- Calculation of docking in loaded condition, if relevant

Our damage assessment survey reports with accompanying photos of the repairs, repair specifications and quantity of the repairs to be done is accepted by many leading marine insurance underwriters.

With the detailed specification of the repairs provided, it will help yard to prefabricate the materials required to carry out repairs which will save the ship time during the dock.

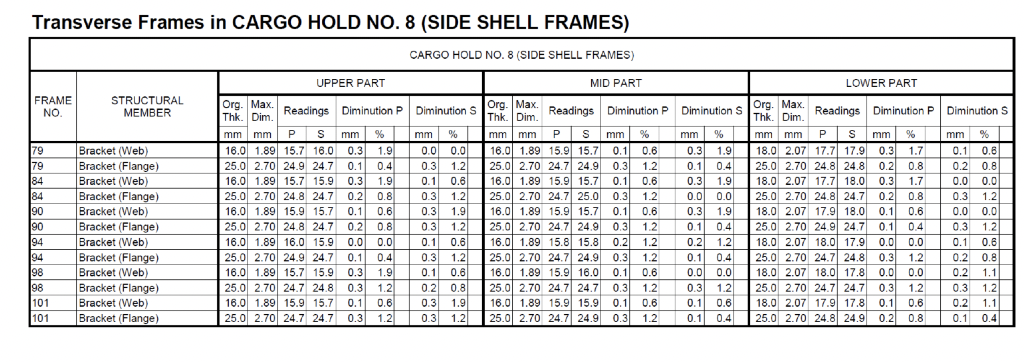

(f) Ultrasonic thickness measurement (UTM) Survey

As per the class rules and regulations all vessels need to undergo Ultrasonic thickness measurement (UTM) survey periodically as:

- Annual survey

- Intermediate survey

- Special survey

- CAP survey

With our expertise in UTM survey technique, we help our clients to understand the condition of the vessel corrosion pattern. Our inspectors are well versed with IACS standards and classification society rules as per the type of survey.

Our inspectors are well versed with all the IACS classification society TM reporting softwares.

Naval Architectural Services

For Basic and detailed design, the team should be well experienced to carry out the design or else the design may not move into reality in shipyard.

Did you know? Our design team - Our Naval Architects, Design engineers, piping engineers, electrical engineers and marine draftsman are very well experienced across various vessels from small to medium sized to large vessels.

Our expertise of design department is:

- Ship Basic and detailed design

- Floating dock basic and detailed design

- Ship conversion design

- Ship modification drawings

- Ship plans upgration

- Strength calculations and analysis

- Stability calculation and booklet preparation

- Sounding table generation

- 3D modelling

- Pipe modification drawings

- Structural modification drawings

Sales and Purchase Services

The second-hand market is particularly significant in terms of value and turnover. With our global connections with various ship owners and managers, we can help you to find the right vessel according to your needs.

Selling ships is a highly specialised skill and, when successful, it can prove to a highly profitable sector of the shipbroking market. But the process is complicated, and the failure rate is high. To have a chance of succeeding, a sale and purchase broker needs to be apt at marketing, maintaining relationships, negotiating, drawing up contracts and assessing documentation

We can help you to complete the deal with ship owners with our global networks.

Green Ship Recycling

When a vessel is ready to be retired, green ship recycling is the most sustainable, safest way to end its service.

With our experienced Naval Architects and HazMat experts, we have familiarity with recycling process practised by recycling yards in Alang. With our expertise we can help ship owners to short list, or select recycling facility, based on any special requirement the owner may have.

We will provide comprehensive day / weekly / monthly reports to ship owners and determine the facility’s ability to comply with ship recycling regulations.

PacMaK DB recycling supervisory teams are well trained and experienced. On-site supervisors attend the ships being recycled daily and liaise closely with the facility’s staff to ensure efficient, safe, and environmentally sound operations and also care of the workforce. The owner is kept regularly updated and advised on the progress of recycling, of any incidents of note within the facility and/or adjacent to it and any fresh requirements by authorities or by new regulations as applicable. This is generally done through detailed and illustrated weekly reports. Serious incidents are reported immediately.

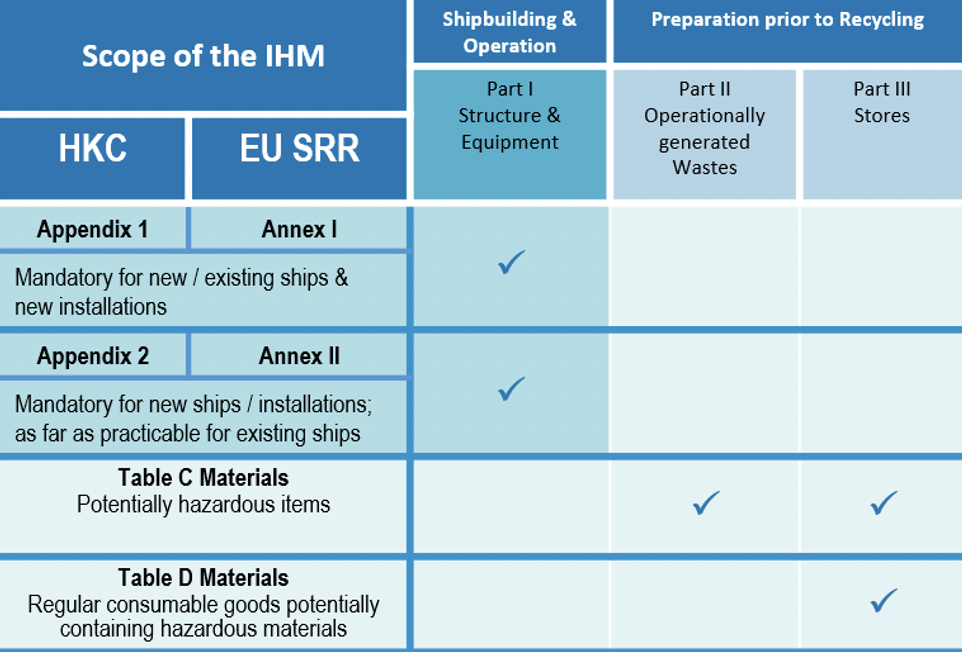

Inventory of Hazardous Materials (IHM) Part I, II and III

With our expertise of HazMat experts, we can carry out IHM survey Part I, II and III for ship owners and managers.

We do IHM Part I reports, which are prepared according to the MEPC.269(68) 2011 Guidelines for the Development of the Inventory of Hazardous Materials, shall be certified by the flag states or by recognized organizations (ROs).

The EU SRR requires investigation of 15 hazardous substances, listed in Annexes I and II to the regulation, while HKC requires 13. In the table below, you can see the details of the Annexes and Appendices as well as the details of the IHM.

Our experienced HazMat experts can provide IHM Management for our clients.

Preparing Bulk Carrier for the Carriage of Containers

Carriage of containers on bulk carriers is a hot topic, and careful planning and preparation is necessary to ensure the safety of the crew, ship and cargo. PacMaK DB experienced Naval Architects teams an help our clients with that.

We can provide the typical documentation required for the carriage of containers on bulk carriers.

- Loading computer system with new GM limits

- Container securing manuals

- Structural strength calculation reports

- Stability booklet and documentations

- Damage stability analysis

- Addendum to the loading / unloading sequences

- Fire & Safety plan addendum

- Navigation documents addendum

- Mooring and towing equipment arrangements

- Hull strength calculation report

- Hatch cover strength calculation report

Ship Chartering

With our global connections we can arrange all type of vessels for chartering on

- Voyage charter

- Time charter

- Bareboat charter

Chartering is an important process as it ensures that our clients cargoes are delivered safely in the most cost-effective manner.

Our expertise will benefit our clients in making them:

- Understand contractual provisions

- Learn how to avoid the potential pitfalls in chartering ships

- Manage charter party dispute that might arise

- Learn about the government laws of the contract

Energy Efficiency Existing Ship Index (EEXI)

With IMO mission on carbon emission reduction and MARPOL Annex VI at MEPC 76, EEXI and regulation 28 the requirement to reduce operational carbon intensity.

As a ship owner or manager, your immediate focus might therefore be on completing your EEXI and improvement calculations if you haven’t done so already.

The EEXI is a technical design related measure. Ships must approve the attained EEXI value.

Our expertise will help clients

- Calculate the EEXI value, including the relevant correcting factors

- Compare the required and attained EEXI values

- Estimate and iterate the engine power limitation (EPL) value

- Generate EEXI technical file

- Guide clients if any retrofit needed to comply the EEXI regulations

Pre-purchase Inspections

We offer pre-purchase vessel condition assessment services on major ports around the world with our global network of expert ship inspectors enabling us to appoint the best inspector nearest to the inspection port without any overhead cost.

Our inspectors have Naval Architect, Chief Engineer and Technical Superintendent backgrounds and conduct the most efficient yet detailed assessments of the vessel condition. With unbiased assessment and judgment, they help to identify businesses’ exposure to potential risks from the purchase of second-hand vessels.

Ship Spare parts

We can provide spares of Main engine, Auxiliary engine, and Auxiliary machineries for our clients across the globe. We can provide OEM spares, Genuine spares and Reconditioned spares for our client’s consideration.